Service Process

1. Sourcing Reliable Bag Materials

Commencing with the meticulous procurement of raw materials, our focus is on meeting the specific functional requirements of various custom-designed bags, including Motorcycle Bags, Functional Backpacks, Tool Bags, and Tactical Vests.

Rigorous inspections of raw materials are conducted to ascertain quality and suitability. Our checks include the use of a yard counting machine to assess fabric quality during the rolling and counting process. Additionally, we scrutinize the woven texture, coating, backing quality, and conduct tear strength tests. This ensures that the selected fabrics are fit for use as surface fabrics, linings, or decorative elements.

Inspector checks fabric quality on fabric inspection machine, uneven dyeing, stains, holes or other flaws

2. Stringent Material Quality Control and Production Requirements

Upon receiving the materials in our warehouse, our technicians verify their compliance with the requested bill of materials. If the materials meet the specifications, our technicians collaborate with the production manager to retrieve them from the warehouse and transport them to the production site. During this process, our technicians also double-check whether the materials align with the production requirements. If any material falls short of the specified requirements or displays defects during the initial visual inspection, our technicians have the authority to reject the goods.

tear strength tests being conducted, to evaluate the resistance of a material against tearing forces.

3. Rigorous Control at Each Manufacturing Stage for a 100% Non-Defective Rate

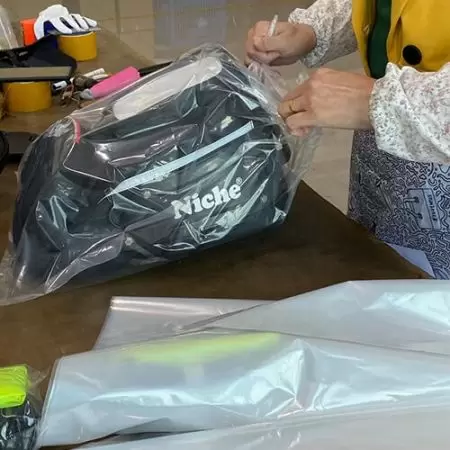

Once materials arrive at the production site, they are allocated to designated sewers for the relevant production and sewing processes. Each sewer is provided with detailed instructions and samples to guide their work, ensuring consistency and quality. In addition to the random checks performed by our production line leaders to address sewing or machine-related issues, our online quality control (QC) staff continually monitors each production line to confirm product quality. Once the components are ready for final assembly, they undergo thorough inspection by a final product QC member. The packaging process involves tasks such as thread trimming, surface cleaning, hardware wrapping, and hang tag attachment. The finished products are then placed in plastic bags with stickers or labels, as per the customer's requirements, and packed into export cartons. Warehouse staff collect the products hourly, storing them in the finished product warehouse area.

4. Expedited Third-Party Quality Inspection and Shipment

Upon completing the goods, we inform the customer within five days to make arrangements for container reservations and payments. Some customers may opt for a third-party inspection before shipping. Once we receive approval from the customer's quality inspection and shipping instructions, we arrange for shipment to the port and load the goods onto the ship.

- Gallery

- we provide high-quality materials and deliver superior products a wide range of bags including motorcycle bags, outdoor backpacks, and toolvests.

- Testing Polyester's Water Repellency, water beads up on the fabric's surface and rolls off.DWR coating applied to enhance water repellency, doesn't turn white after rubbing.

- Sewing a rubber badge around the piping, ensuring a secure, durable and to prevent the edges of the bag from abrasion.

- Sew the side pannel and bottom of Tank bag, non slip leather.

- Sewing a belt with a double-needle stitch, sew two parallel lines simultaneously.

- Manual inspection stations ensure tool vests or bags meet quality standards for size, stitching, and functionality.

- Finished bags are packed into polybag for efficient packaging.

- loading goods into container, shipping and delivery to customers.