Work With Us

A Tailored Motorcycle Gear Manufacturing Working with Niche

Welcome to working with Niche, where we invite you to embark on a unique journey in crafting motorcycle bags, hardshell backpacks, and tool bags tailored to your specific needs. As your dedicated partner, we take pride in offering a streamlined process that ensures the creation of high-quality gear precisely matching your specifications. Ready to begin? Simply fill out the inquiry form at the bottom of this page, and we'll be with you every step of the way.

1. Transforming Your Vision into Exceptional Reality – Motorcycle Bags, Backpack and Tool Bags at the Forefront of Innovation

Motorcycle bags, backpacks, and tool bags can let each client bring their design artwork, hand drawings, or conceptual ideas, and watch as our team of experts transforms them into exceptional, functional bags. With a blend of professionalism and expertise, we ensure that each piece is not just crafted, but thoughtfully engineered to meet your specific requirements.

Our dedicated team is committed to providing you with top-notch suggestions on structure, fabric, materials, and more. We understand that every detail matters, and we strive to exceed your expectations by ensuring that your unique gear not only meets but surpasses them.

In addition to collaborating closely with you, we offer a range of in-house design options that can be tailored to meet your specific market requirements. This flexibility allows us to create a product that perfectly aligns with your vision and caters to your target audience.

At Niche, we value your vision and take pride in our meticulous process. We are dedicated to transforming your ideas into a tangible and exceptional reality. By working with us, you will experience unparalleled craftsmanship that sets Niche apart from the rest.

Let us bring your unique gear to life. Join us on this collaborative journey and witness the magic of turning your vision into a reality that stands out from the crowd.

2. Pattern Creation and Initial Prototype: Motorcycle Bag & Backpack

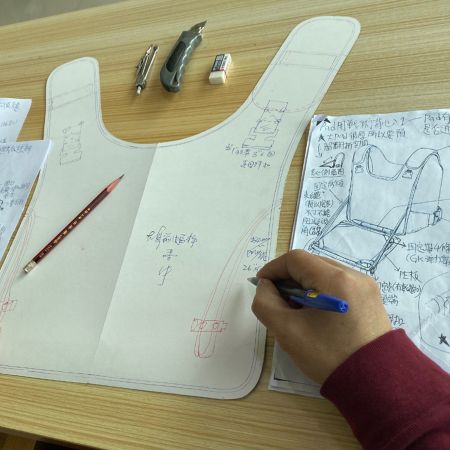

Once the design framework, structure, and material specifications are in place, our master craftsman will create paper patterns tailored to your bag. This is where your journey with us begins. We invite you to work with us by sharing your unique design concepts, ensuring that every detail aligns with your vision. Whether you have a clear plan or seek professional guidance, our experts are here to collaborate, offering insights into structure, fabric, and materials. These patterns are then handed over to our sample room staff, who meticulously calculate material usage, perform hand cutting, and create logo tooling. The result is the production of a first prototype sample. Typically, this process takes 2-3 weeks. We'll share detailed images of the prototype sample with you for initial evaluation. After your approval based on these images, you can arrange for the prototype sample to be shipped to you. Please note that the first prototype sample is primarily for structural confirmation and is made using the materials available at hand.

3. Your Journey, Your Gear: Seamless Collaboration in Crafting Motorcycle Bags and Backpacks

Upon receiving your feedback and comments on the prototype, including any material specification changes, we will work closely with you to implement your modifications. This may involve adjustments to the paper patterns and the creation of a second prototype sample. This time, we use the exact materials and components that meet your design requirements.

After your approval based on these adjustments, we invite you to continue working with us by arranging for the second prototype sample to be shipped to you. This step allows for a closer inspection of the refined craftsmanship and design, ensuring that every element now perfectly aligns with your expectations.

4. Specialized Parts Development Crafted for Your Vision: Innovating Motorcycle Bags and Backpacks

Embark on a precision-driven journey with Niche as we delve into the realm of crafting specialized components tailored specifically to your project. Committed to delivering excellence, we offer a personalized approach through our Work With Us program, ensuring that your unique needs are not only met but exceeded.

At Niche, we understand the paramount importance of precision and attention to detail when it comes to specialized components. Our team of experts is dedicated to working closely with you, ensuring that every aspect of your vision is brought to life. From the initial concept to the final completion, we are here to guide you through the entire process.

With our extensive experience in the industry, we have honed our skills in developing specialized parts that meet the highest standards of quality and functionality. Our state-of-the-art facilities and cutting-edge technology enable us to create components that are not only visually appealing but also durable and reliable.

Collaboration lies at the heart of our approach. We firmly believe that by working together, we can achieve remarkable results. Our team of engineers and designers will collaborate with you, taking into account your specific requirements and preferences. Through open communication and regular updates, we ensure that you are involved in every step of the development process.

Furthermore, our Work With Us program is designed to provide you with a seamless experience. We understand that each project is unique, and therefore, we tailor our services to meet your individual needs. Whether you require a small batch of specialized components or a large-scale production, we have the flexibility and expertise to accommodate your requirements.

When you choose Niche, you can be confident that you are partnering with a company that is dedicated to delivering exceptional results. Our unwavering commitment to excellence, combined with our passion for innovation, sets us apart in the industry. We take immense pride in our ability to transform your vision into reality, ensuring that your specialized components not only meet but exceed your expectations.

- Gallery

- Introducing the new products Tools waist bag belt vest

- design a preliminary sketch to confirm bag style or provide a sample of bag

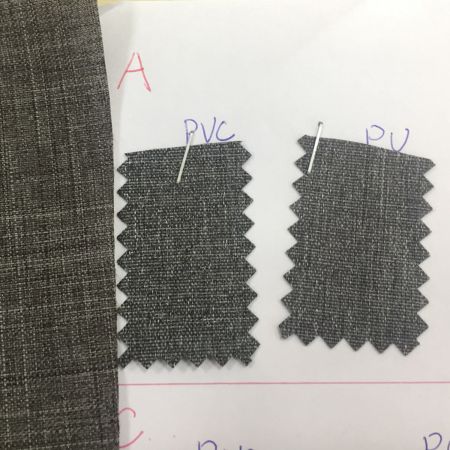

- selected colors and materials for sample production

- selected a material for sample production

- professional sewing worker, installing eyelets, tool bags

- using electric grooving iron during duty belt making process

- Stitching sandwich mesh padded Back panel of backpack

- we can do OEM/ODM all kinds of soft bags and hardshell backpacks.